WE LISTEN TO YOU

We care about the people we work with. That means our customers, our suppliers and each other. We listen, we adapt.

We care about the people we work with. That means our customers, our suppliers and each other. We listen, we adapt.

Pump diaphragms

For Flowplant

Rubber problems don’t come across my radar anymore. Martin’s is a safe pair of hands and I’d recommend them thoroughly – we know that if they can’t solve our problem, then it’s probable that nobody can.

Steve Smith, Director of Engineering, Flowplant.

Moulded insert for glasses case

for Ayres London

I was extremely pleased with the service we received from Martin’s. They communicated with us throughout the design and manufacture process and understood our brand ethos – both the need for utmost quality and protection, as well as ensuring that, ultimately, our product is a thing of beauty.

Mark Mason, Ayres London

Moulded pad with embossed logo

for Vehicle Developments

This project was really important to us; it was a high-profile vehicle and one that we hoped would help us to secure further business. The service and the final product designed by Martin’s was exactly what we were looking for and enabled us to supply our customer with an extremely high quality finish.

Derek Ray, Vehicle Developments

Glass compactor entry point

For Glassbusters

We are very happy with the quality of the final product. The communication that we have had with Lisa throughout the manufacture process has been second-to-none and has given us real confidence in your service and delivery, both of which are critical to our business.

Will Debenham, Commercial Manager, Glassbusters

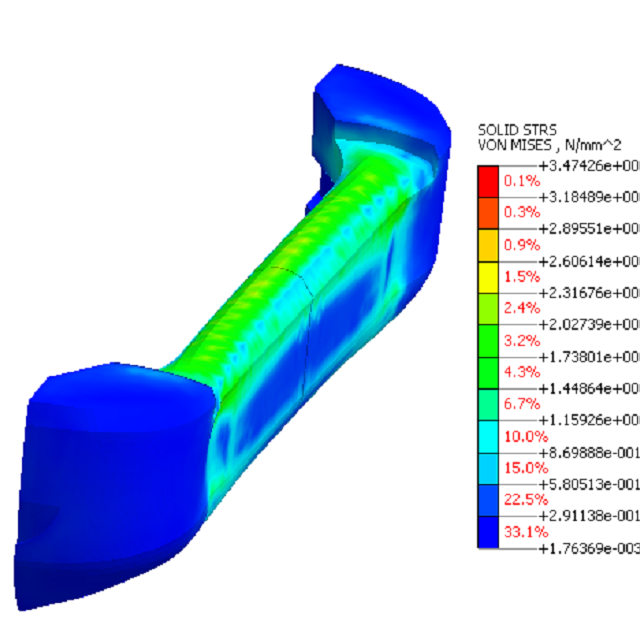

FEA for rubber bumper

to pass US legislative crash tests

We are extremely pleased with the final result and are proud of the vehicle that we were able to present to the customer – particularly given its pole position on the crash test trials. Martin’s Rubber helped us with a solution that not only worked under the most critical of tests, but it was one that would also provide weight – and therefore cost – savings for our customer.

Lead Engineer, Ian Clifton

Design, prototype and manufacture of flexible sleeve for a fuel system

for Kopter

Martin’s Rubber were recommended to us by another of our suppliers, and we now understand why they have a reputation for delivering solutions to the tightest of requirements. We are really pleased with the final parts and are looking forward to getting them into service.

John Martin, Lead Engineer, Kopter.

Cam chain guides, custom manifold and airbox seal

for Bike It DRT Kawasaki racing team

We need our suppliers to be versatile, innovative and responsive. As always, Martin’s delivered all three of those elements on this project and helped in getting us to pole position again.

Steve Dixon, Bike It DRT Kawasaki racing team

Automated updates for every order

The weekly Open Order Report you send us every Friday is very good, we love it and it makes a big difference to us to see where our jobs are without having to ask; we only need to speak to you if the report shows something will now be late, which is great. In fact I am now asking all my other suppliers why they cannot do the same, using Martin’s Rubber as an example of how to do it well.

Mark Blincow, Supply Chain and Logistics Manager, Ricardo UK.

Delivery to order schedule in volume

for BlankMaster

As a manufacturer we are well aware of the importance of designing for consistency, quality and repeatability. We are extremely happy with both the product and the service that we have received from everyone at Martin’s – we are now able to deliver our own product with confidence.

Gary Compton, Managing Director, BlankMaster

Know exactly what you want? Upload your drawings so we can provide a tailored solution

Get in touch with us today by email [email protected]