WE OPTIMISE YOUR PERFORMANCE

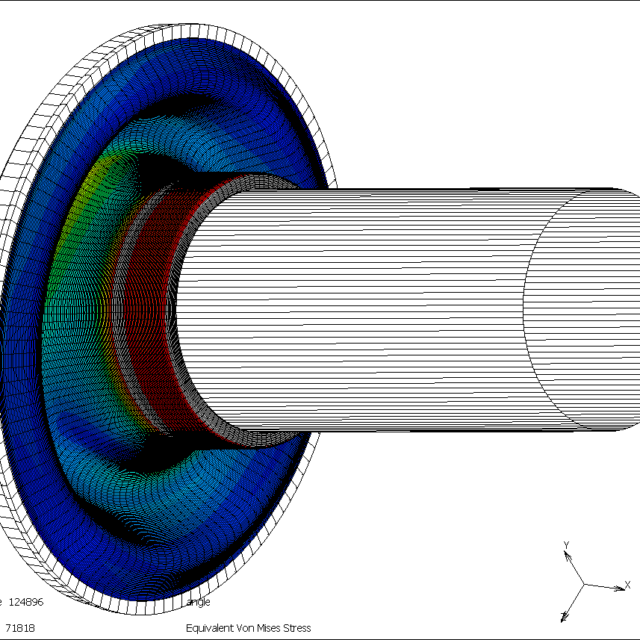

We do it using non-linear FEA, analysing your product’s suitability for its intended application.

We will help you get the edge.

Contact our FEA expert today

We do it using non-linear FEA, analysing your product’s suitability for its intended application.

We will help you get the edge.

Contact our FEA expert todayOptimisation of a product design

An understanding of the environmental limitations of your design

An improved product life cycle

Knowledge of how and why an existing part is failing in operation

A solution that will reduce trial and test time

We understand that. Which is why we will analyse any rubber compound using non-linear FEA. Anyone who knows something about measuring a stress/strain relationship will know that offering to test only a handful of core material grades isn’t enough. We will take a moulded sample of the actual material you want to manufacture your product from, and use the data from that specific compound mix to run the analysis. Not only that, but if you are bonding your rubber to a plastic, metal or composite part, we will include the properties of that material and look at how the relationship will impact the rubber component.

Products like CV boots are critical to the performance of vehicles, and are a prime candidate for non-linear FEA. If you want to find out the types of analysis used, which areas it will help to improve and when to undertake FEA on CV boots, read our downloadable PDF below.

To find out how a well known delivery truck manufacturer used FEA as part of their crash test strategy before moving to the production phase, download the case study below.

Know exactly what you want? Upload your drawings so we can provide a tailored solution

Get in touch with us today by email [email protected]