WE ENGINEER

We use our expertise in materials and specific marketplaces to collaborate on projects where performance is critical.

How we can help

We use our expertise in materials and specific marketplaces to collaborate on projects where performance is critical.

How we can helpMarginal gains for a competitive edge

Collaborative development for best-in-class

Unusual aesthetics

Specific split-line locations or processing requirements

Complex insert preparation

Weight-or size-restricted solutions

Pairing of unusual materials

Combinations of unusual mechanical properties

Reverse-engineering

The impossible

Advice on rubber product development

Prototype development and testing

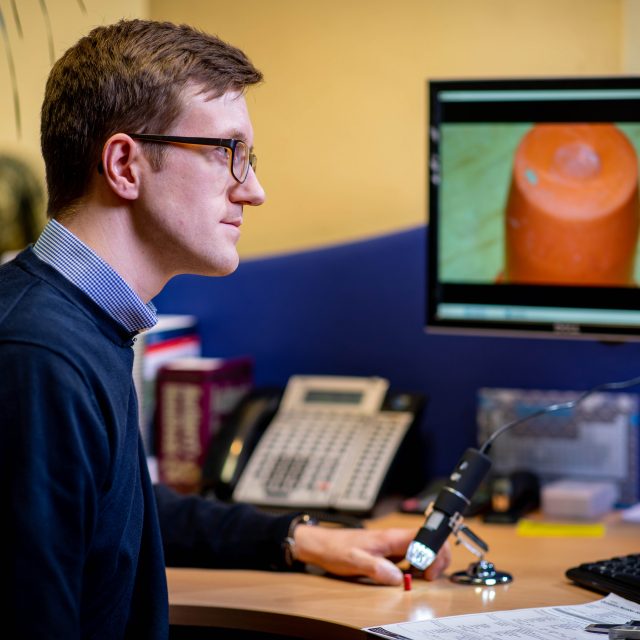

Izaak Watson

Technical Manager

Collaborating for your success

We employ some of the most experienced and innovative industry experts, and we carefully combine our skills in materials knowledge, toolmaking, product testing and engineering, along with our extensive experience in high-performance products, to provide the very best in collaborative design. Designing with rubber is what we do, and we will work with you and your designers and engineers to create a product that fits your particular needs, whether the challenge lies in weight-saving, aerodynamics, environment or manufacturing.

Q. You know what you need the product to do but are unsure of which material to select and how it will then perform.

A. We can assist with material selection, and then either run Finite Element Analysis (FEA) prior to manufacture, or we can make a low-volume tool and run some prototype rubber parts for real-world testing or for submission to a testing house.

Q. You have a part that already works in situ, but you need to improve the performance to cope with a more extreme working environment; faster (and therefore hotter) moving parts, a more corrosive chemical contact, a greater load.

A. We will look at how the part currently functions and the areas that you need to improve. We will work with you to establish the most likely solution; a bonded rubber and PTFE seal to cope with higher temperatures, a more resilient elastomer or we might run some trials and load-test alternative materials for analysis of the larger load.

Q. You have a part that needs to function mechanically, but it also needs to have a high standard of finish beyond that of a solely functional component.

A. We will work with you to understand both the function of the parts as well as the critical aesthetic areas and the look you need. We will design a tool and select a material with both in mind so that any trimming is minimal and away from the visual parts of the product, whilst maintaining the properties required.

Know exactly what you want? Upload your drawings so we can provide a tailored solution

Get in touch with us today by email [email protected]